The electrolytic engraving kit for iron sheets is a kit with which you will have the chemical components to make your personalised engraved iron sheets.

CONTENTS OF THE ELECTROLYTIC ETCHING KIT FOR IRON SHEETS

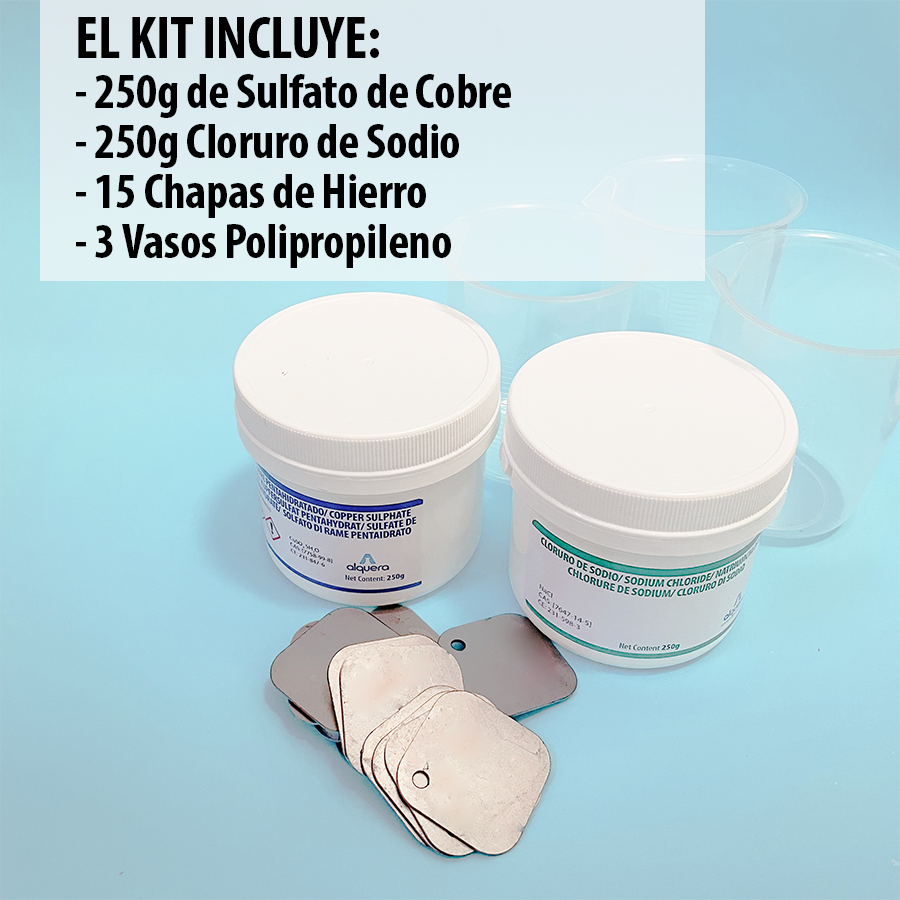

The kit includes:

- 15 units of Iron plates

- 250g Copper Sulphate

- 250g Sodium chloride (common salt)

- 3 Polypropylene cups of 250ml.

The kit does not include:

- Nail polish

- Alcohol/Acetone for cleaning

- Sandpaper of different grits

STEP BY STEP HOW TO ENGRAVE IRON SHEETS

We show you the detailed step-by-step in video

- Place the copper sulphate and sodium chloride (common salt) in a glass of water. 3 tablespoons of each.

- Taking the Iron Plate

- Clean the entire surface very well with alcohol, including sanding if there is any rust residue.

- Cover one side of the sheet tightly with tape and make a border on the other side.

- You can make a design on the piece with the enamel, you can use the pen or punch to achieve finer strokes. You could also use a sticker, or use tracing paper and use your own stencil.

- Immerse the piece and leave it for 1-2h. The longer the sheet remains in the solution the more it will etch.

- Every 15min remove the reddish layer that is formed.

- Remove the plate and immerse it in water,

- Clean the sheet metal: Remove the tape and remove the enamel with acetone and sand the surface well with multi-grit sandpaper.

WHAT YOU LEARN FROM THIS EXPERIMENT

- The reaction between iron and copper sulphate allows you to study the electrochemical corrosion of iron, where the copper ion acts as an oxidising agent.

- It allows you to see the 2 elements in an oxidation-reduction, redox reaction, as the iron is oxidised into solution and the copper ion is reduced to copper metal and deposited on the iron.

- This experiment allows you to see how an active chemical acts on the metal.

TECHNICAL EXPLANATION

Redox reaction. This experiment shows a practical application of an oxidation-reduction reaction.

The concept we have of iron oxidation is the layer of iron oxide that is deposited on its surface when oxidised by air. It is a layer of Fe2O3 (iron oxide). In this case, instead of being oxidised by oxygen, the iron will be oxidised by the copper ion. The iron, Fe, will oxidise to iron ion, Fe2+ and Fe3+ passing into the solution (this causes the solution to change colour).

On the other hand, the copper ion Cu2+ of the sulphate will be reduced to copper Cu. This can be seen by a thin red layer deposited on the iron. This layer is not fixed and can be easily removed from the plate.

The reactions that are therefore taking place are:

CuSO4 + Fe -> FeSO4 + Cu

The role of the common salt, sodium chloride, is to facilitate the movement of electrons for the reaction to take place.

Reviews

There are no reviews yet.